SA Office of the Technical Regulator: Three workplace fatality investigations

During the second half of 2020 the Office of the Technical Regulator investigated three work related fatalities involving licensed electrical workers performing their normal daily occupational duties. Our observations and tests carried out at each incident found evidence and conditions that were consistent with a person receiving a fatal electrical shock.

During the second half of 2020 the Office of the Technical Regulator investigated three work related fatalities involving licensed electrical workers performing their normal daily occupational duties. Our observations and tests carried out at each incident found evidence and conditions that were consistent with a person receiving a fatal electrical shock.

When these incidents involve an electrical worker, it has an emotional impact with the OTR’s investigating officers.

All the incidents had similarities where each electrical worker either chose to work live or did not effectively confirm positive electrical isolation. In addition to not positively isolating the supply, other contributing factors included inadequate PPE, inappropriate or non-insulated tools, confined working conditions and the incorrect function selected on a digital multimeter.

It is also significant to point out that no RCDs were installed on the circuits involved. Whilst they were not required at the time of the original installation, the risk of electric shock would have been significantly reduced. However, RCDs are not recognised as a sole means of basic protection therefore when working on or around live equipment RCDs must not be relied upon or substituted for isolation or other effective methods of protection.

Plumber changing domestic hot water service

Unrestricted electrical worker in business roof cavity working on ducted air conditioning

Unrestricted electrical worker repairing commercial air conditioner on shopping centre roof

Incident 1: Plumber with restricted electrical licence changing over a domestic hot water service (HWS):

There was no lockable isolator adjacent to the HWS unit

There was no lockable isolator adjacent to the HWS unit- The electrical worker disconnected a faulty existing 240V directly connected HWS at the unit’s terminals. This was done after allegedly confirming that there was no electrical supply.

- The supply active and neutral conductors were terminated with cable connectors.

- The worker changed over the faulty HWS with a new HWS, connected the plumbing connections and pressurised the unit.

- The worker removed active connector with bare hands and received an electrical shock between the live active conductor and earth wire or conductive earthed part(s).

Three other very notable details to highlight:

- The off-peak tariff element of the electrical meter was programmed for a daytime controlled load which appears to have initiated and energised the HWS circuit just prior to the victim reconnecting the electrical supply to the new HWS unit. The generation of renewable energy such as solar has created a situation where far more electricity is now generated in the middle of the day which creates a condition where supply exceeds demand, consequently causing grid instability and reliability. In an effort to control this a “soak” of the excess of generation can be programmed with certain types of meters.

- The circuits including the HWS circuit breaker were not labelled in the switchboard. The electrical workers licence restrictions and competency in identifying correct circuit isolation may have played a significant role.

- Although not required during the original installation or for repairs, a lockable isolation switch adjacent to the HWS would have provided ultimate control and isolation for the victim. The latest edition of AS/NZS 3000 now has this as mandatory requirement for new installations or alterations to directly connected water heaters.

Incident 2: Unrestricted electrical worker fault finding ducted reverse cycle air conditioner within beauty salon roof space:

Fault finding a noisy 240V zone control actuator and removing from service.

Fault finding a noisy 240V zone control actuator and removing from service.- There was no isolation of circuit.

- There were cramped working conditions.

- The cover was removed from the zone actuator, exposing live soldered connections on a printed circuit board (PCB).

There was multiple conductive earth return paths in the area.

There was multiple conductive earth return paths in the area.- The worker received an electrical shock, likely due to contact between the PCB’s active soldered connection and earthed conductive part(s).

Working in confined locations particularly within roof spaces, without isolating the electrical supply or following safe work practices is risky and can expose oneself to unforeseen dangers. This could be existing unsafe wiring or just simply losing your balance and inadvertently coming into contact with a live part you are working on. The potential of electric shock is somewhat further increased if a return path through conductive earthed components is in the vicinity of the working area.

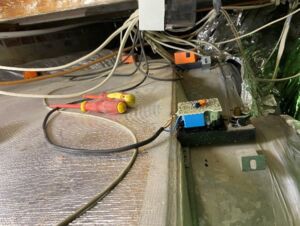

Incident 3: Unrestricted electrical worker fault finding and repairing a commercial air conditioner on a shopping centre roof:

The electrical worker was working on a condenser unit control board for a tenancy air conditioning system

The electrical worker was working on a condenser unit control board for a tenancy air conditioning system- The multimeter onsite was set on the incorrect function for the desired test

- There was no positive isolation confirmed

- Non-insulated pliers were used to strip a live conductor

- The worker had Inadequate PPE

- There were multiple conductive earthed return paths in the area

- The worker received an electrical shock between an active conductor and a conductive earthed part (i.e. roofing material or A/C chassis) likely while using uninsulated pliers.

This situation reiterates the importance of positive isolation by proving the correct operation of meters on a known source before use and being familiar with the functional selections on the meter. During this investigation the multimeter onsite was found to be set on the Volts DC range, which when testing for AC voltages would have presented a misleading reading to the victim.

There will be circumstances where working on or in the proximity of live conductors is necessary or unavoidable therefore under the Electricity Regulations it is essential to have suitable protection from live parts in particular appropriate PPE, barriers and the use of suitable equipment and insulated tools. Additionally, when undertaking work that involves danger of direct contact with live conductors, it is crucial that safe work practices are applied such as carrying out work with a competent assistant who is and suitably trained in rescue and resuscitation.

All these tragic incidents had one underlining contributing factor – complacency. It is an extremely dangerous mindset when working, particularly when performing electrical work. Routine repetitive tasks, overconfidence and being disengaged from the task can send you into “auto pilot”. Furthermore, unreasonable demands and conditions issued by clients and employers can place additional pressure on workers. This can lead to poor decision making and taking short cuts and/or unnecessary risks which can have devastating consequences.

This article has been republished from the South Australian Government with permission